Continuous Furnace Solutions for High-Efficiency Industrial Heat Treatment

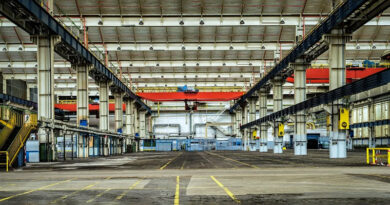

In modern industrial manufacturing, efficiency, consistency, and productivity are key drivers of success. Among the various heat treatment technologies available today, continuous furnaces stand out as an essential tool for large-scale production operations. These furnaces offer uninterrupted heating processes and are widely used in industries such as automotive, aerospace, steel, ceramics, and metallurgy. If you’re aiming to enhance throughput while maintaining excellent product quality, a continuous furnace is the perfect solution.

What Is a Continuous Furnace?

A continuous furnace is a type of industrial furnace designed to heat-treat materials or components as they pass through the system in a steady, continuous flow. Unlike batch furnaces that require intermittent loading and unloading, continuous furnaces are ideal for high-volume manufacturing because they provide a streamlined, automated, and energy-efficient solution.

Materials are moved through the furnace using mechanisms like conveyor belts, rollers, pushers, or walking beams, depending on the design and application. The controlled atmosphere and temperature zones allow for precise heat treatment of each product.

Types of Continuous Furnaces

-

Belt Conveyor Furnace – Used for sintering, annealing, brazing, and tempering small components. Products are placed on a metal mesh belt that moves them through different heating zones.

-

Roller Hearth Furnace – Ideal for heavy or flat products like steel plates, billets, or sheets. Rollers convey materials smoothly and uniformly.

-

Pusher Type Furnace – Used in forging and reheating applications, materials are pushed through the furnace in trays or containers.

-

Walking Beam Furnace – Commonly used in steel mills for reheating slabs and billets. Provides accurate movement and prevents product damage.

-

Tunnel Furnace – Used in ceramics, glass, and powder metallurgy. Products move through a long tunnel under consistent heat.

Key Features and Benefits

✅ High Throughput

Continuous furnaces are engineered to handle large volumes of materials, making them ideal for mass production.

✅ Uniform Heating

Multiple temperature zones ensure consistent heating and optimal metallurgical properties across all products.

✅ Energy Efficiency

Modern continuous furnaces are designed with advanced insulation and energy-saving controls, helping reduce operational costs.

✅ Automated Operation

Integrated PLC systems and SCADA controls allow for real-time monitoring, automated adjustments, and minimal human intervention.

✅ Scalable Design

Furnaces can be customized based on your floor space, production volume, and specific process requirements.

Applications of Continuous Furnaces

Continuous furnaces are widely used across various industries, including:

-

Automotive – For heat treatment of gears, shafts, fasteners, and other components.

-

Aerospace – For treating high-performance alloys and precision parts.

-

Metal Industry – In processes like annealing, normalizing, carburizing, and stress relieving.

-

Ceramics and Glass – Used for firing and curing operations.

-

Powder Metallurgy – Ideal for sintering of metal powders into solid parts.

Why Choose a Trusted Continuous Furnace Manufacturer?

Choosing the right furnace partner is critical to long-term production success. A reputed manufacturer ensures:

-

Custom-designed furnaces to suit your specific materials and process flow.

-

Advanced safety and energy controls for reliable and safe operation.

-

Robust post-installation support including commissioning, training, and maintenance.

Manufacturers like JR Furnace & Ovens have decades of experience in designing and supplying high-quality continuous furnaces that perform under rigorous industrial demands. Their ability to deliver both standard and fully customized solutions has made them a preferred choice across India and overseas.

Conclusion

A continuous furnace is more than just a piece of equipment—it is a productivity powerhouse that can transform your manufacturing efficiency. With uniform heating, seamless operation, and energy optimization, continuous furnaces are the future of industrial heat treatment.

Whether you’re expanding your production line or upgrading existing systems, investing in a high-quality continuous furnace can deliver significant ROI and operational improvements. Plan your visit to a trusted furnace manufacturer and discover how advanced thermal technology can elevate your business to the next level.